Rebuilding a Platform

Overview

During my tenure, the app evolved from a whiteboard concept to an efficient, high-performing platform that shipped over 2 million orders annually and growing. The platform managed orders from multiple third-party APIs and a client-facing store.

As the product designer for the engineering team, I owned the entire design process from ideation to validation for this platform. I drove initiatives, worked closely with my cross-functional partners. As the scrum Product Owner, I wrote the tickets and managed the development sprints.

TIMELINE

May 2018 – September 2021

ROLE

Lead Product Designer — user research, design, project management, scrum product owner

TEAM

Two Engineers

Product Designer (me)

TECH STACK

React and Go

Challenge – Version 1

Create and deploy a beta version of a complete rebuild of the print and ship software in 1 month. Refine to version 2 by the following month to be ready for the holiday season volume. Prioritize accuracy and efficiency. Consider role-based permissions, white labeling capabilities, and multiple facility locations.

User Need

Warehouse workers were struggling to complete orders on time.

Warehouse managers were having trouble tracking and hitting the SLAs.

Customer service had difficulty tracking and replacing orders.

Business Need

New seasonal contracts were in place based on daily SLAs. The old software did not support third-party API integration or the required volume of data.

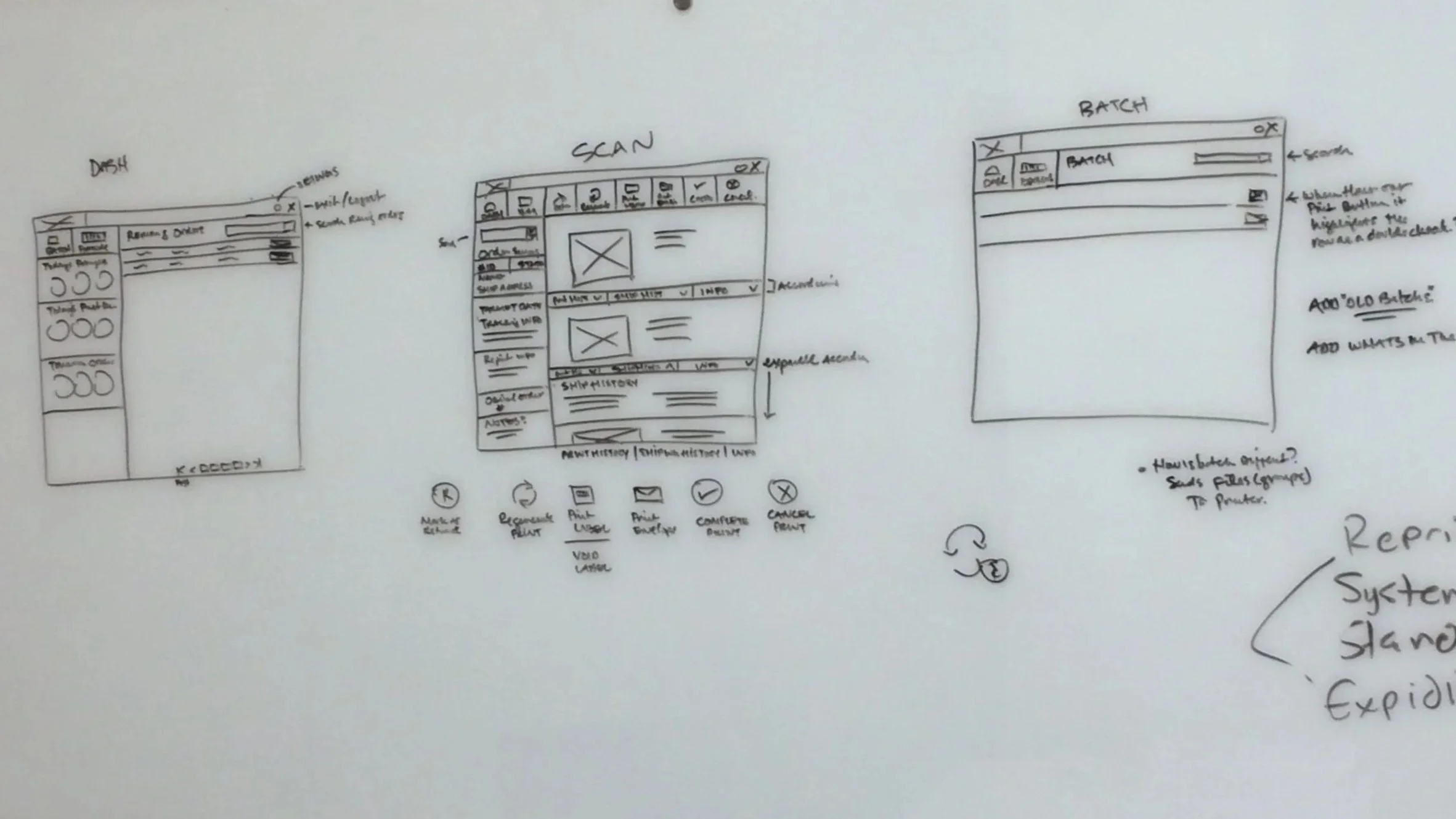

whiteboard of initial design

Outcome – Version 1

We hit our deadline and released for the Fall holiday season. Due to the timelines, we didn’t have time to validate. During the season, I collected user feedback with extensive field studies and full-team surveys.

Challenge – Version 2

Make it better!

User Need

The warehouse improved the SLAs to 80% but was having difficulty seeing the screens due to the colors not working with the lighting in the warehouse, and the text was too small to read at a distance. Initial assumptions were that the users were working right next to the screens, but it turned out that they were usually at least 3 feet away.

Business Need

New seasonal contracts were honored at a lower price due to the number of orders under the SLA. New agreements for the Spring holiday season required a 90% SLA.

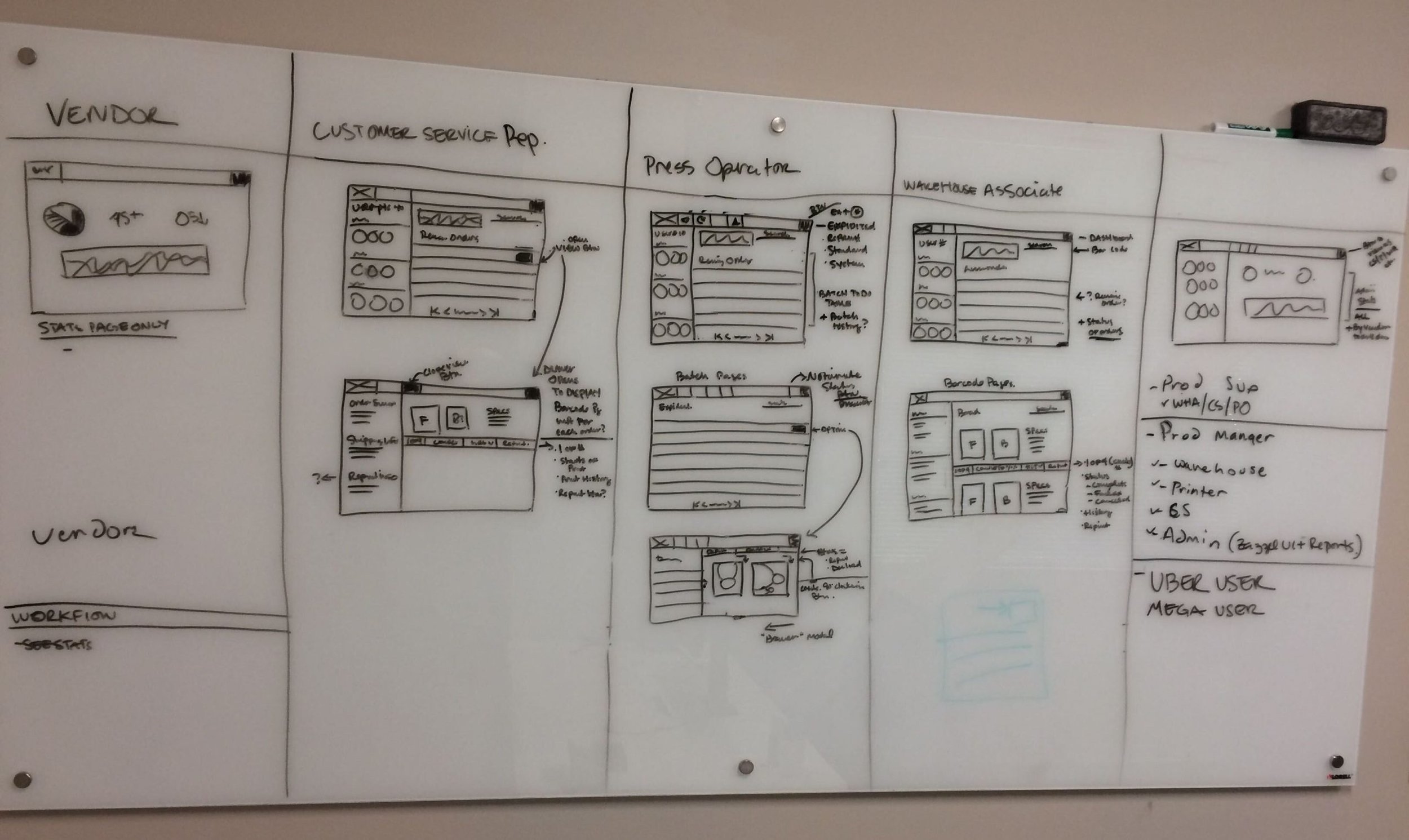

Mapping Out Permissions Levels

Outcome – Version 2

Efficiency improved to 85% but still needed to be above 90%.

Another round of field studies revealed that users could see the screen better, but still struggled with the warehouse lighting and the workflows required that the user put their scanner down to advance to the next step, which slowed them down.

Challenge – Version 3

Improve efficiency by reworking workflows and enhancing UI readability.

User Need

Users were still struggling to hit their SLAs.

Business Need

New seasonal contracts required 90% SLA and they were only hitting 85%.

Outcome – Version 3

I reworked the UI and workflows, and the resulting SLAs ranged between 91% and 93%, hitting our goal of above 90%!

Further Initiatives

Over the next two years, I partnered closely with the COO, the two Facilities Managers, and the Head of Customer Service on over 40 product initiatives that enhanced the platform's efficiency and features. The following are some examples of these initiatives.

Order Allocation

When I joined the team, the company had one facility, but later expanded. To meet immediate needs, I worked with engineers to create a manual method for moving orders in the console, which evolved into bulk-moving tools and status reports that assisted warehouse team leads in managing their teams.

Outcome

Engineers are resourceful in finding the quickest solutions to problems, and sometimes these shortcuts can lead to significant results.

Reduce Short Shipped Orders

We encountered the issue of "short shipping"—sending fewer items than ordered. To tackle this, the Facilities Manager and I developed a "binning" system. We set up numbered bins on physical shelving at each station, linked to digital bins in our app for tracking.

Outcome

As a result of these measures, we were able to reduce short orders by approximately 20%..

Improve Accuracy

One of our third-party accounts faced a challenge matching die cut shapes of cards to printed envelopes. I drew each shape, added icons to print slips and order details, updated the QA final shipping screen, and created cheatsheets for the warehouses.

Outcome

These measures collectively helped both the veteran staff and the holiday seasonal employees enhance their accuracy rates by over 15% in both facilities.

Reduction Paper Usage

For a third-party product line, we included a printed sheet for the shipping slip and one for the invoice. By combining these sheets into a single printout that was produced simultaneously with the main piece, we achieved significant efficiency.

Outcome

This approach led to a reduction in both paper and ink costs for the entire product line.